600V

Li-ion

Battery

Optimization

Formula

Electric

Berkeley

Python

SolidWorks

Matlab

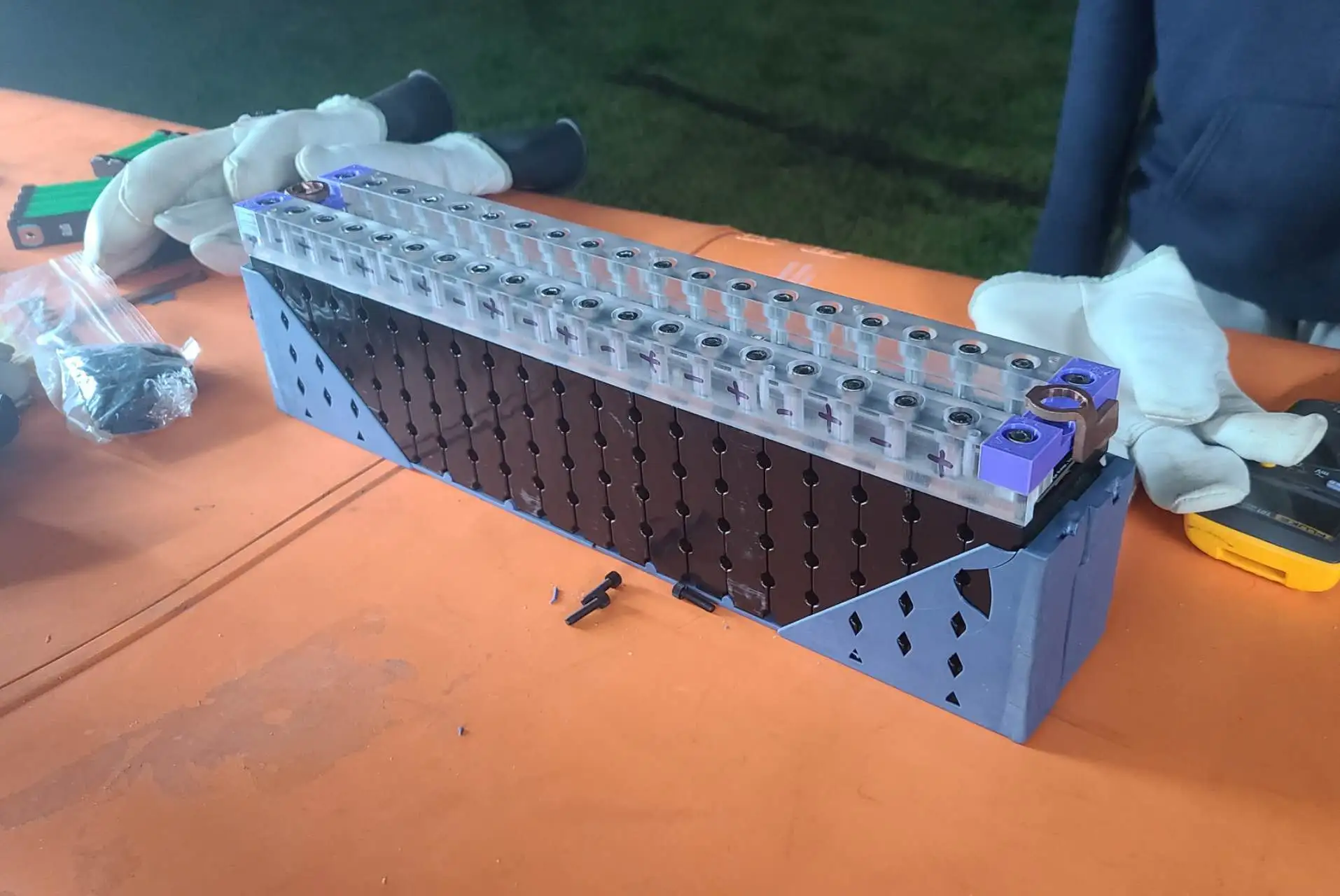

Custom battery pack design in SolidWorks

Custom battery pack design in SolidWorksOverview

This project is a part of my work as a member in the Formula Electric at Berkeley team, a UC Berkeley student EV club building fully electric race cars. As it is known, the battery is the heart of an electric vehicle. Its efficiency is tightly related to the car's power draw, capacity, temperature, and many other parameters. There are many off-the-shelf battery modules available from companies like Energus and Enepaq. The team has been using 1s4p Molicel 18650 modules in the past, but it is extremely difficult to cool and lack efficiency in power extraction. Hence we embarked on the journey to explore custom battery packs, a task all the world's leading EV companies are also tackling.

Battery segment made using off-the-shelf modules from Energus

Battery segment made using off-the-shelf modules from EnergusWhat?

This project includes designing a python program that computes optimal battery pack configurations based on battery cell characteristics and making the battery from scratch after validating the model.

The project is consist of a few stages:

1) Research and development, where key information about building a custom pack and related manufacturers were gathered.

2) Design and iteration, where multiple CAD designs were made for validation.

3) Design reviews, where we articulated our design to Tesla and Apple engineers for feedbacks.

4) Prototype and testing, where rough parts were made to validate design, and cell testing happened.

5) Manufacturing and assembly, where final production starts.

While the project did not reach stage 5 due to lack of funding, many design reasonings and prototypes indicated success of the project. The design also passed multiple rounds of design reviews with Tesla and Apple engineers who have or had experience designing electrical parts for either EV or other systems.

Custom battery pack fit test

Custom battery pack fit testWhy?

Custom pack is extremely desirable because it allows for fully custom packaging and power extraction from the battery cells. We are allowed to rearrange the configuration to create custom parallel and series count, we are able to use custom BMS (Battery Management System) boards, and we are also allowed to give more space for cooling, which is important when regenerative breaking is a feature we want to implement to the car (regen breaking generates a lot of heat). Moreover, custom pack is a terrific way to learn more about how battery works.

Rear of the SN3 model, where energus modules were used

Rear of the SN3 model, where energus modules were usedHow?

There were a few major tasks I was responsible of and completed since the start of the project. Every process follows the first principles of design.

1) Researched in busbar materials, mainly different types of aluminum, copper, and nickel alloys) to determine the best material to use for conducting electricity throughout the pack.

2) Calculated of the minimum busbar cross-sectional area given the max current we will be expecting.

3) Analyzed the effect of material has on spot-welding method (better electrical conductivity = better heat conductivity = harder to weld = need super expensive spot-welder or else can't assemble).

4) Wrote a Python script to model the battery pack output given the cell characteristics. This is used to compute the optimal pack configuration given the desired parameters (e.g. power draw, capacity, series count, etc.).

5) Incorporated Matlab simulation results for thermal management in battery cooling into final design.

6) Designed a CAD model of a battery segment according to the determined configuration, and printed prototypes of the segment through 3DP for testing.

7) Represented the subteam to present design to Tesla and Apple engineers and successfully passed all three reviews.

This is a project I will continue to work and advise on in the future, and will update periodically here.